Latin American aerospace news and aircraft projects

- Thread starter MiG-29SMT

- Start date

More options

Who Replied?MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

The CH-8 is an Argentine ultralight two-seat helicopter for civil use. It is made entirely of aeronautical materials and the blades are made of composite materials. The power plant used is a 135 HP Rotax EPA R917Ti

The 2-crew ultralight has a maximum speed of 194 km/h, a service ceiling of 4,500 meters and a flight time of 2.5 hours.

It currently has 100 devices sold all over the world.

CICARE Helicopteros S.A.

The 2-crew ultralight has a maximum speed of 194 km/h, a service ceiling of 4,500 meters and a flight time of 2.5 hours.

It currently has 100 devices sold all over the world.

CICARE Helicopteros S.A.

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

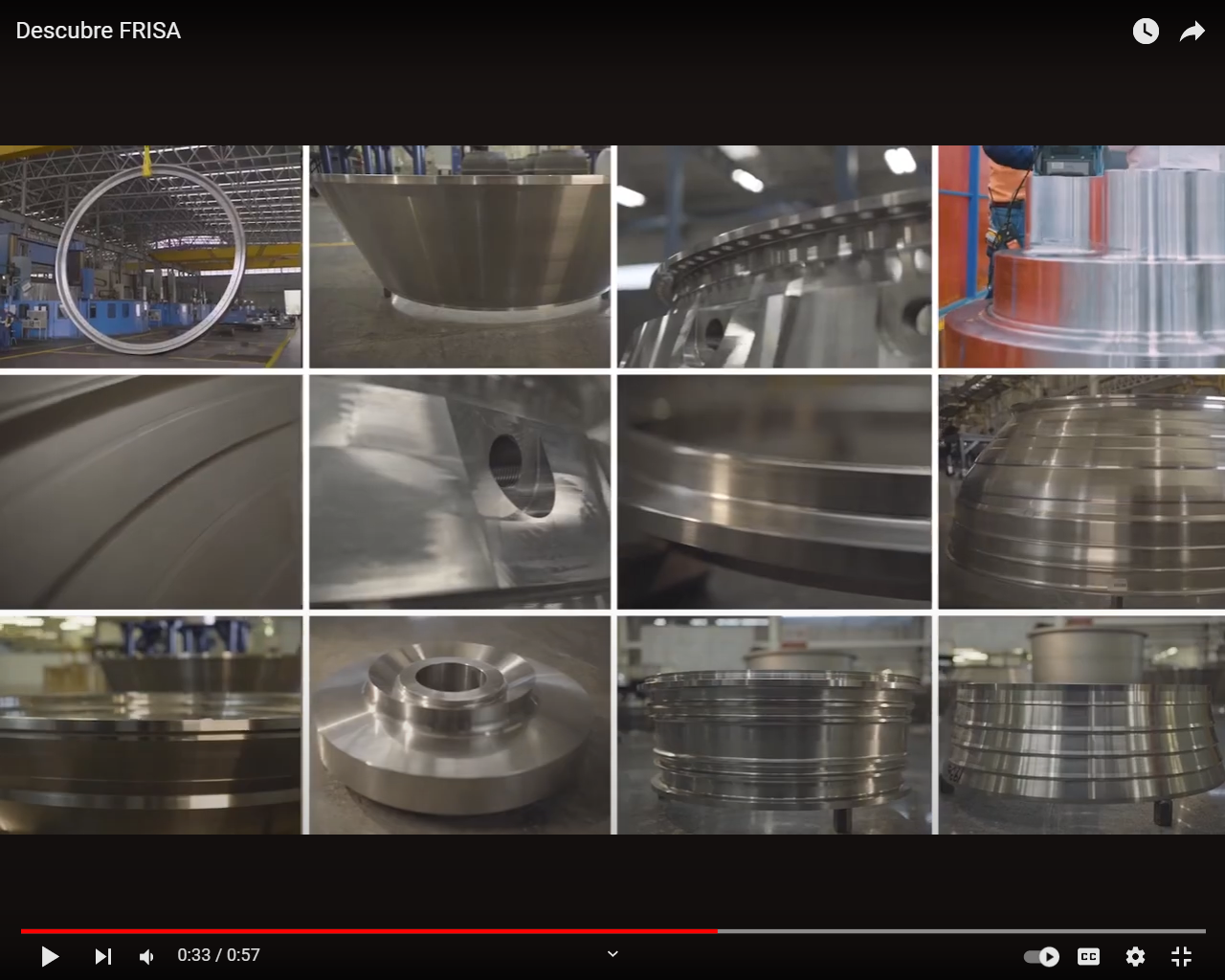

At FRISA Aerospace we have extensive experience in providing rolled rings for critical components in aircraft jet engines.

So when you see a plane take off, you'll know FRISA is there.

Frisa aerospace is Mexican company located in the city of Monterrey, Nuevo Leon, Mexico

So when you see a plane take off, you'll know FRISA is there.

Frisa aerospace is Mexican company located in the city of Monterrey, Nuevo Leon, Mexico

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

Aerospace manufacturer Walbar Engine Components opens its second plant in Sonora

18 September, 2018

Walbar is a long-established manufacturing and engineering company, founded at Tempe, Arizona in 1951. Though it’s not a household name, it is well known amongst engine manufacturers worldwide: Walbar’s components can be found in the hot section of turbine engines around the world. Its main products include blades, vanes and related components used in aircraft and industrial turbine engines. The company was acquired in 1986 by Coltec Industries, and later, in 1999 by Goodrich. In the following year, they started a plan to relocate their labor-intensive manufacturing from several US locations to the port city of Guaymas in Sonora, Mexico. Later, in 2012, Goodrich was taken over by United Technologies Aerospace Systems (UTAS).

Walbar’s facility in Mexico’s Sonora state proves its ability to deliver for the global aviation industry

Walbar’s facility in Mexico’s Sonora state proves its ability to deliver for the global aviation industry

Sonora strengthens its aerospace arm with the inauguration of a new plant in Hermosillo, Sonora. AT Engine, a joint project by Mexican Altaser Aerospace and the German Aerotech launched in 2017, inaugurated its manufacturing plant this Sunday. The 3.5ha plant represented a US$200 million investment and is expected to generate 400 aerospace jobs. It will focus on the production of engine parts and other aviation technologies to strengthen the state’s value chains.

Altaser Aerospace is a fully Mexican company created in 2012 that specializes in CNC machining of metal parts, components and assemblies. The company, part of Grupo Punto Alto, originates from Chihuahua and produces complex welded assemblies, components, fittings, railings and chassis, among other products. This new plant will allow Altaser Aerospace and Aerotech to strengthen their presence in northern Mexico and to cater to their partners north of the border.

While the global aerospace sector slowed down after the COVID-19 crisis, Sonora’s aerospace industry has remained active and even received investments during this period. In late 2020, the state announced the construction of a new plant from aerospace testing supplier Applied Technical Services (ATS), which would expand the company’s capabilities in the state from 200 to 1,000 employees.

AT Engine Inaugurates Sonora Plant

Sonora has a new aerospace manufacturing plant courtesy of AT Engine, which is expected to generate 400 aerospace jobs.

The CFM International LEAP is a high-bypass turbofan engine, successor of the CFM56. It delivers an up to 20% improvement in fuel consumption while maintaining reliability and life-cycle maintenance cost.

For more information about the CFM LEAP Engine, visit their official website.

Last edited:

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

Aerospace Turbine

Cost optimised solution for volume component delivery

Plant and Location

Optimum Turbine Manufacture’s production home is in Hermosillo, Sonora, Mexico

www.optimumturbines.com

www.optimumturbines.com

Cost optimised solution for volume component delivery

Plant and Location

Optimum Turbine Manufacture’s production home is in Hermosillo, Sonora, Mexico

Optimum Turbine Manufacture

Optimum Turbine Manufacture brings substantial new capacity on-stream in the production of vanes, segments, inserts and seals, with proven operational and engineering management.

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

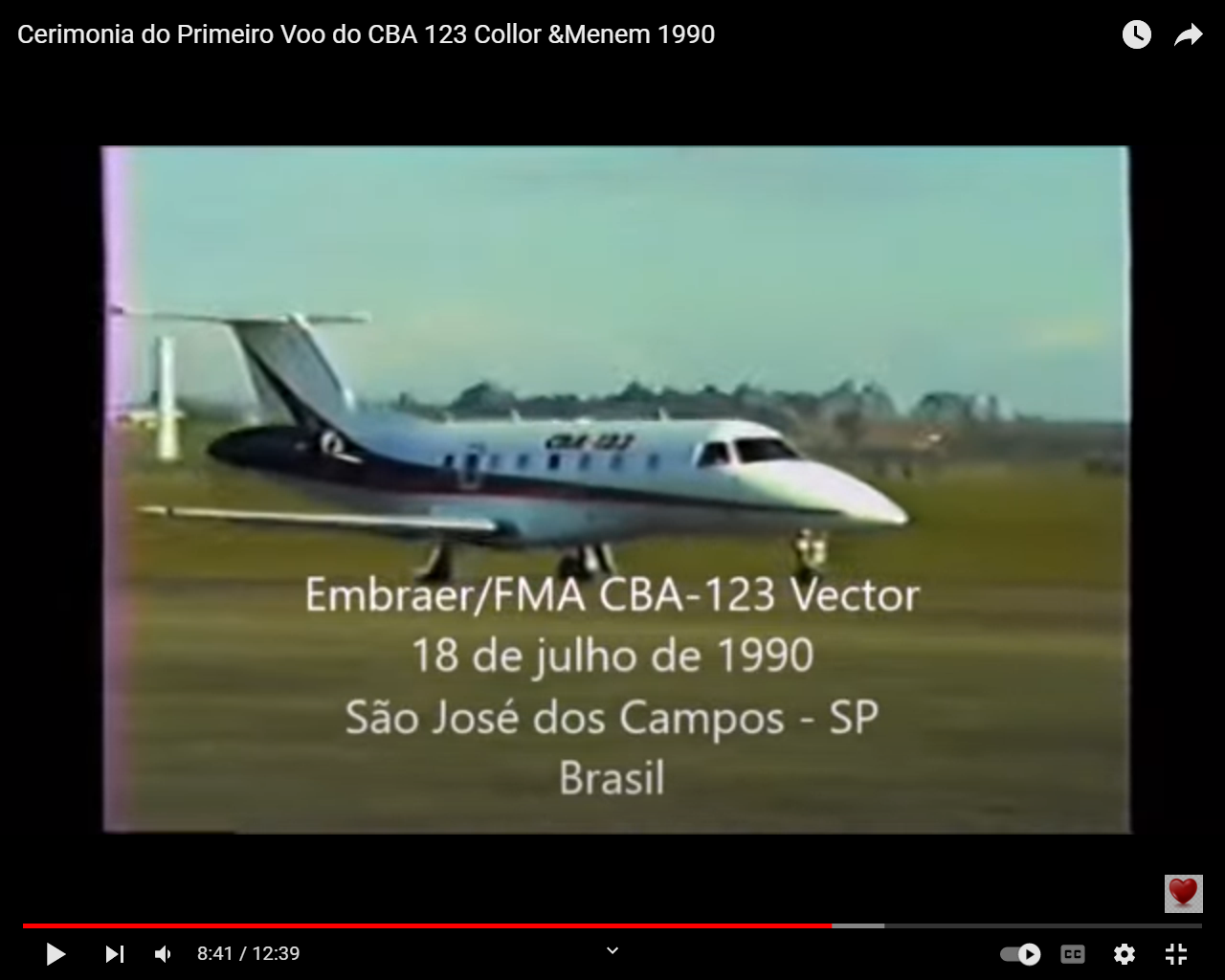

Vector” is an aircraft with capacity for 2 crew and 19 passengers, intended for regional transport. It was the result of an aeronautical cooperation project between Brazil (EMBRAER) and Argentina (FMA - Fabrica Militar de Aviones), called “CBA-123”, and flew for the first time (PT-ZVE) on July 18, 1990. . Being considered one of the most modern aircraft of its time, including cutting-edge technology in avionics, aerodynamics and propulsion, there were only two prototypes built, which were dismantled after the premature end of the project, which was due to high production costs. The curious thing about this plane are the engines near the end of the fuselage, with the propellers inverted (positioned behind the engines).

The example on display (registration PT-ZVB) was restored, along with the other prototype (registration PT-ZVE), by SENAI interns (under the coordination of EMBRAER) and incorporated into the Aerospace Museum's collection in August 2009.

Technical specifications

Manufacturer: Empresa Brasileira de Aeronáutica S.A. - EMBRAER / Fabrica Militar de Aviones - FMA – Brazil and Argentina

Engine: 2 Garret TPF351-20A turboprops of 1,219 s.h.p

Military Designation: --

Length: 18.5 m

Wingspan: 16.46 m

Height: 5.6 m

Empty Weight: 4,900 kg

Maximum Speed: 593 km/h

Range: 1,610 km

Armament:

www2.fab.mil.br

www2.fab.mil.br

The example on display (registration PT-ZVB) was restored, along with the other prototype (registration PT-ZVE), by SENAI interns (under the coordination of EMBRAER) and incorporated into the Aerospace Museum's collection in August 2009.

Technical specifications

Manufacturer: Empresa Brasileira de Aeronáutica S.A. - EMBRAER / Fabrica Militar de Aviones - FMA – Brazil and Argentina

Engine: 2 Garret TPF351-20A turboprops of 1,219 s.h.p

Military Designation: --

Length: 18.5 m

Wingspan: 16.46 m

Height: 5.6 m

Empty Weight: 4,900 kg

Maximum Speed: 593 km/h

Range: 1,610 km

Armament:

CBA-123 Vector | EMBRAER - FMA - MUSAL

www2.fab.mil.br

www2.fab.mil.br

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

The Embraer/FMA CBA 123 Vector was a turboprop aircraft designed for regional services, and could carry up to 19 passengers. The plane was developed by a consortium between the Brazilian company Embraer and the Argentine Military Aircraft Factory (at that time, a state industry), which is why the acronym "CBA" was incorporated into its name, which means "Brazilian Cooperation." Argentina". The aircraft was one of the most modern turboprops of its time, including technological innovations in avionics, aerodynamics and propulsion.

In 1985, the economic integration of South America seemed to advance with the good progress of the negotiations for the formation of Mercosur between the Brazilian and Argentine governments. In 1986 and as a means to strengthen cooperation between both countries, the proposal for joint development of an aircraft between Embraer and FMA arose.

The costs and workload would be distributed between Embraer and FMA in a 2:1 ratio. The design included high-tech components: leading thrust engines (with the propellers "backwards", as opposed to classic engines, which generate an air current that "pulls" the aircraft), supercritical profile wings, engine control FADEC and EICAS and EFIS avionics systems. The name "Vector" was chosen in an international competition from more than 6,000 proposals.

The first prototype of the Vector first flew on July 18, 1990 without problems. The official presentation, which took place on July 30, 1990, was attended by the then presidents of Brazil, Fernando Collor de Mello, and Argentina's Carlos Saul Menem.

Unfortunately for Embraer and FMA, the high technology that should have ensured the success of the CBA 123 was the reason for its failure and withdrawal. The final cost of the device, 5 million US dollars, was too high to be assumed by the general market. Added to this problem was the difficulty for the Brazilian government to continue investing money due to the political crisis resulting from the impeachment process of Fernando Collor de Mello.

The CBA 123 Vector project, which cost US$300 million, was canceled with only two prototypes built. The third prototype has been stored in Argentina with an 80% degree of progress. Despite the failure, the project meant for Embraer to reach maturity in its work with high technology, which would lead to the development of the successful series of Embraer 145 reactors.

For its part, Argentina had made the political decision to cancel the pre-existing IA 68 ATL project, to begin the development of the IA 70 in conjunction with Brazil. The IA 68 was being developed in collaboration with Dornier (with whom it had developed the IA 63 Pampa) and was in an advanced state of development. The cancellation of both the IA 68 and the IA 70 / CBA 123 was a serious blow to the Argentine aeronautical industry.

In 1985, the economic integration of South America seemed to advance with the good progress of the negotiations for the formation of Mercosur between the Brazilian and Argentine governments. In 1986 and as a means to strengthen cooperation between both countries, the proposal for joint development of an aircraft between Embraer and FMA arose.

The costs and workload would be distributed between Embraer and FMA in a 2:1 ratio. The design included high-tech components: leading thrust engines (with the propellers "backwards", as opposed to classic engines, which generate an air current that "pulls" the aircraft), supercritical profile wings, engine control FADEC and EICAS and EFIS avionics systems. The name "Vector" was chosen in an international competition from more than 6,000 proposals.

The first prototype of the Vector first flew on July 18, 1990 without problems. The official presentation, which took place on July 30, 1990, was attended by the then presidents of Brazil, Fernando Collor de Mello, and Argentina's Carlos Saul Menem.

Unfortunately for Embraer and FMA, the high technology that should have ensured the success of the CBA 123 was the reason for its failure and withdrawal. The final cost of the device, 5 million US dollars, was too high to be assumed by the general market. Added to this problem was the difficulty for the Brazilian government to continue investing money due to the political crisis resulting from the impeachment process of Fernando Collor de Mello.

The CBA 123 Vector project, which cost US$300 million, was canceled with only two prototypes built. The third prototype has been stored in Argentina with an 80% degree of progress. Despite the failure, the project meant for Embraer to reach maturity in its work with high technology, which would lead to the development of the successful series of Embraer 145 reactors.

For its part, Argentina had made the political decision to cancel the pre-existing IA 68 ATL project, to begin the development of the IA 70 in conjunction with Brazil. The IA 68 was being developed in collaboration with Dornier (with whom it had developed the IA 63 Pampa) and was in an advanced state of development. The cancellation of both the IA 68 and the IA 70 / CBA 123 was a serious blow to the Argentine aeronautical industry.

Last edited:

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

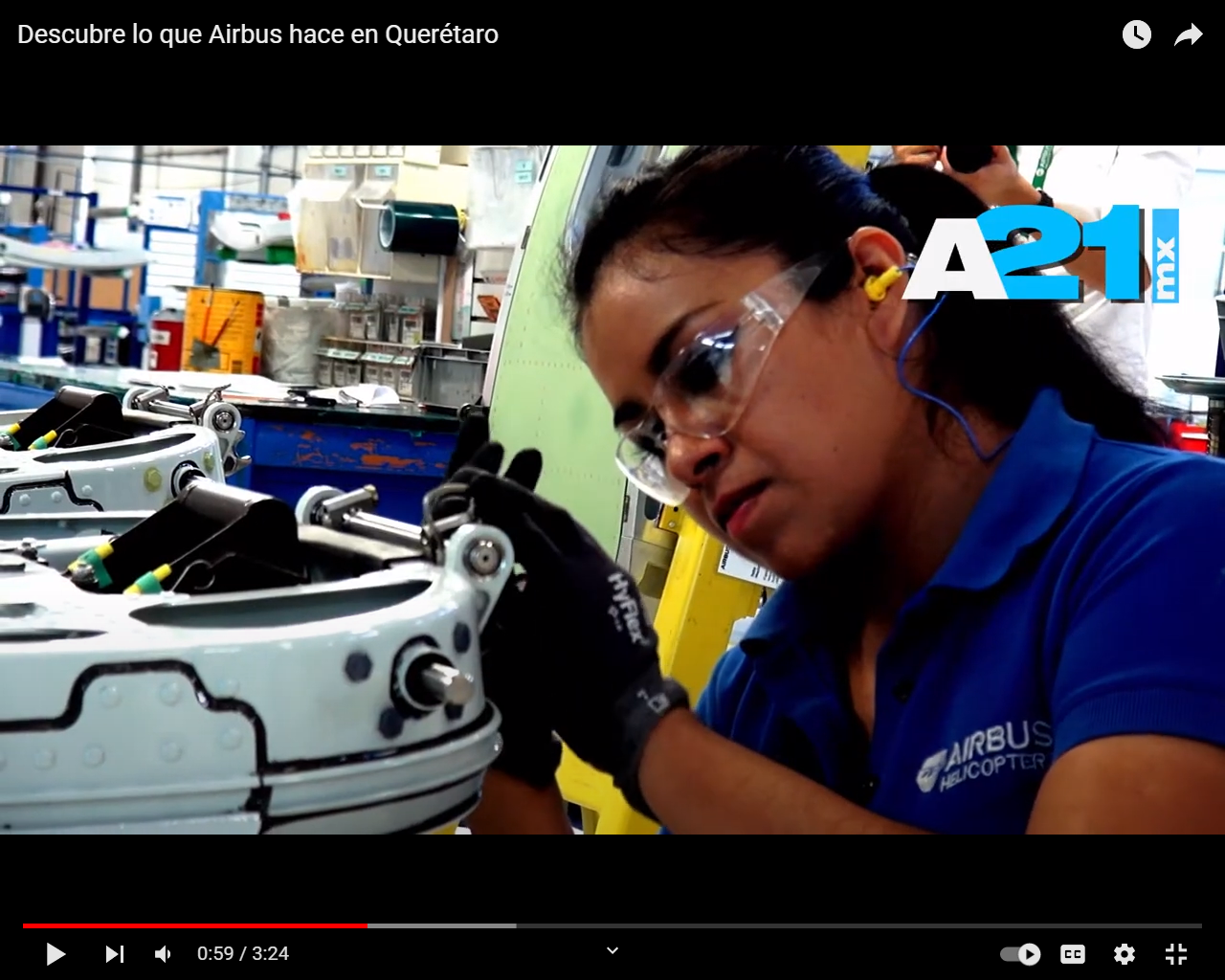

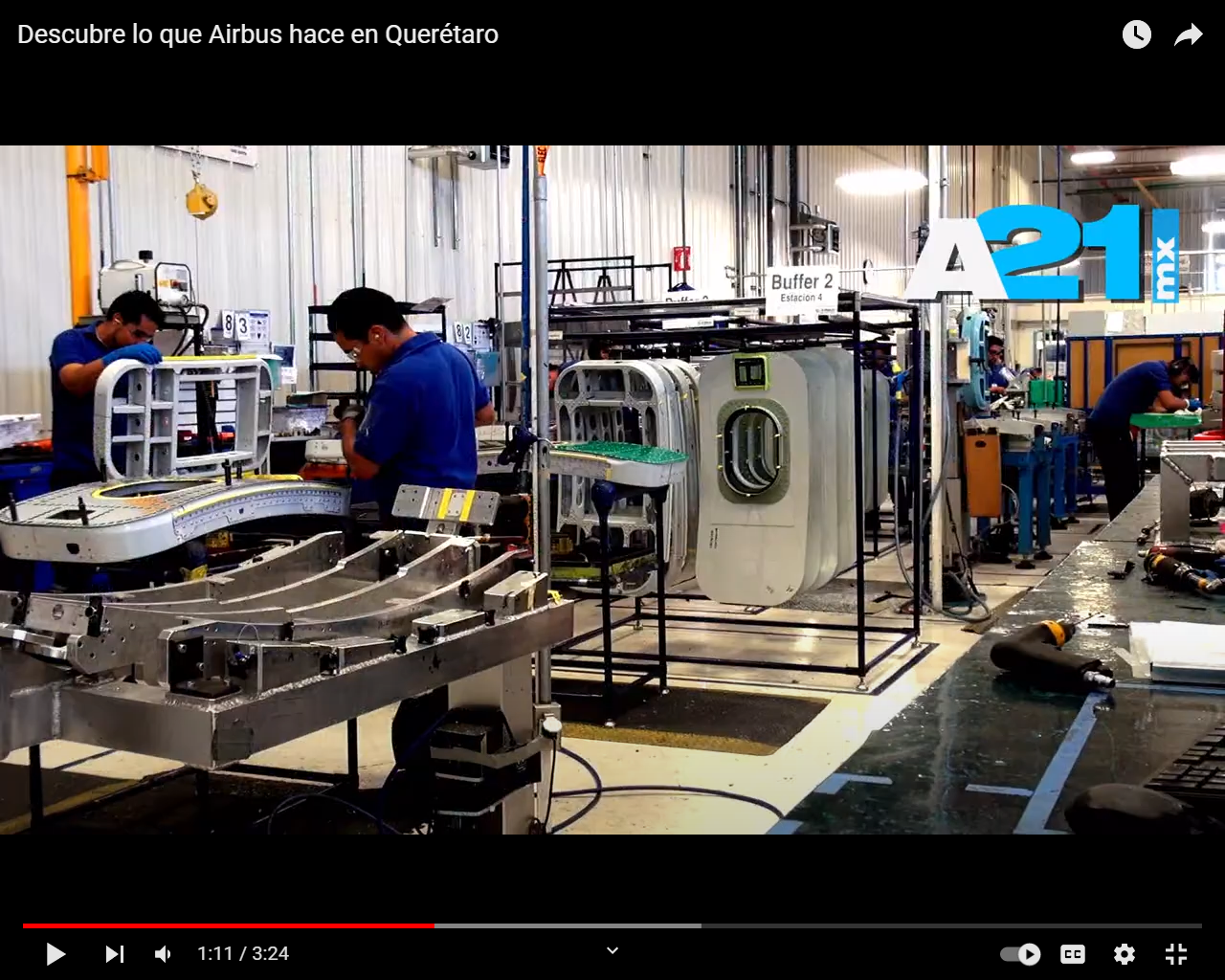

Did you know that in Querétaro there is an Airbus plant, one of the most important aviation companies in the world? The unit produces thousands of doors for its aircraft and services hundreds of helicopters throughout Latin America. Forbes México visited these facilities; Find out how they do it

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

Bombardier's leadership team visited our state-of-the-art facility in Querétaro, Mexico. They had the pleasure of meeting and seeing the incredible work of the team of skilled professionals technicians. Since establishing a manufacturing facility in Mexico in 2006, Bombardier continues to show its commitment to the country, by helping the development and growth of its aerospace industry.

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

Mexico while supporting Airbus Helicopters’ metallic aerostructures activities

26 September 2017 Querétaro, Mexico

Share

Daher today inaugurated its newest logistics and industrial facility, which supplies Airbus Helicopters’ facility in Querétaro, Mexico, dedicated to Metallic Aerostructures Activities.

Located in a 3,200-sq. meter building, this facility supplies Airbus Helicopters’ nearby production center of metallic aerostructures, which notably includes the production of over wing emergency exit doors and bulk cargo compartment doors for single-aisle jetliners.

Daher’s responsibilities at its new Querétaro site underscore the company’s expertise across a full spectrum of capabilities, from product and process engineering, industrial services and machining to supply chain logistics and transportation. Material management to the delivery of finished doors. The scope of Daher’s operations at Querétaro includes forecasting and procurement of parts and chemicals required for the A320 door production; management of inbound material shipped by Airbus Helicopters in Germany to Mexico; customs clearance; along with inspection and warehousing.

After the material is accepted in Daher’s Querétaro facility, the company performs on-site pre-cutting of aluminum plates used in the doors, then delivers all door components to Airbus Helicopters for production. The process is completed by Daher’s reception of the finished doors from Airbus Helicopters; followed by their packaging and shipment to A320 final assembly lines.

“Such an end-to-end capability is unique to Daher, and it builds on the expertise from our business base that is equally balanced by industrial services and logistics,” said Nicolas Orance, Senior Vice President of Daher’s Aerospace and Defense Business Unit. “With the functions performed at Querétaro, we consider it a ‘logistics factory’ instead of the traditional logistics platform.”

Orance added that the Querétaro facility is aligned with Daher’s strategy of placing resources in close proximity to its customers, and ensuring flexibility in the range of services offered. Current employment is 20 persons – with the majority hired locally and trained for logistics, procurement, engineering methods and metal cutting for the aluminum plates. Enhancing Daher’s footprint in Mexico for new business opportunities.

This new operation also reinforces Daher's presence in Mexico, positioning it for the anticipated expansion of Airbus Helicopters' production at the location, and for future business opportunities within the Querétaro region – a major aerospace manufacturing cluster – as well as elsewhere in the country to serve aviation, automotive and other sectors. Daher already has a factory in Nogales, Mexico, where it produces composite airframes.

Daher has provided logistics services for Airbus Helicopters in a growing partnership that began in 2004, and today encompasses support for the production of rotor craft at Airbus factories in France, Spain and Germany.

www.daher.com

www.daher.com

26 September 2017 Querétaro, Mexico

Share

Daher today inaugurated its newest logistics and industrial facility, which supplies Airbus Helicopters’ facility in Querétaro, Mexico, dedicated to Metallic Aerostructures Activities.

Located in a 3,200-sq. meter building, this facility supplies Airbus Helicopters’ nearby production center of metallic aerostructures, which notably includes the production of over wing emergency exit doors and bulk cargo compartment doors for single-aisle jetliners.

Daher’s responsibilities at its new Querétaro site underscore the company’s expertise across a full spectrum of capabilities, from product and process engineering, industrial services and machining to supply chain logistics and transportation. Material management to the delivery of finished doors. The scope of Daher’s operations at Querétaro includes forecasting and procurement of parts and chemicals required for the A320 door production; management of inbound material shipped by Airbus Helicopters in Germany to Mexico; customs clearance; along with inspection and warehousing.

After the material is accepted in Daher’s Querétaro facility, the company performs on-site pre-cutting of aluminum plates used in the doors, then delivers all door components to Airbus Helicopters for production. The process is completed by Daher’s reception of the finished doors from Airbus Helicopters; followed by their packaging and shipment to A320 final assembly lines.

“Such an end-to-end capability is unique to Daher, and it builds on the expertise from our business base that is equally balanced by industrial services and logistics,” said Nicolas Orance, Senior Vice President of Daher’s Aerospace and Defense Business Unit. “With the functions performed at Querétaro, we consider it a ‘logistics factory’ instead of the traditional logistics platform.”

Orance added that the Querétaro facility is aligned with Daher’s strategy of placing resources in close proximity to its customers, and ensuring flexibility in the range of services offered. Current employment is 20 persons – with the majority hired locally and trained for logistics, procurement, engineering methods and metal cutting for the aluminum plates. Enhancing Daher’s footprint in Mexico for new business opportunities.

This new operation also reinforces Daher's presence in Mexico, positioning it for the anticipated expansion of Airbus Helicopters' production at the location, and for future business opportunities within the Querétaro region – a major aerospace manufacturing cluster – as well as elsewhere in the country to serve aviation, automotive and other sectors. Daher already has a factory in Nogales, Mexico, where it produces composite airframes.

Daher has provided logistics services for Airbus Helicopters in a growing partnership that began in 2004, and today encompasses support for the production of rotor craft at Airbus factories in France, Spain and Germany.

Daher enhances its footprint in Mexico while supporting Airbus Helicopters’ metallic aerostructures activities - Daher

Daher today inaugurated its newest logistics and industrial facility, which supplies Airbus Helicopters’ facility in Querétaro, Mexico, dedicated to Metallic Aerostructures Activities. Located in a 3,200-sq. meter building, this facility supplies Airbus Helicopters’ nearby production center of...

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

This is a report that the local Puebla television station did about the Avipro light aircraft factory with headquarters in Atlixco.

Approximately five months after Bearhawk Aircraft announced a two-seat, taildragger kit design—the Companion—the Austin, Texas-based company has delivered the first two airplanes.

Both of the new owners, Chad Marks and Greg Charest, are new to aircraft building, and both are expecting assistance from Mark Goldberg of AviPro (the Atlixco, Mexico-based builder of Bearhawk’s quickbuild kits), who, they say, has been very supportive so far. The build process is expected to take a few years, based on data from previous Bearhawk builders.

www.flyingmag.com

www.flyingmag.com

Approximately five months after Bearhawk Aircraft announced a two-seat, taildragger kit design—the Companion—the Austin, Texas-based company has delivered the first two airplanes.

Both of the new owners, Chad Marks and Greg Charest, are new to aircraft building, and both are expecting assistance from Mark Goldberg of AviPro (the Atlixco, Mexico-based builder of Bearhawk’s quickbuild kits), who, they say, has been very supportive so far. The build process is expected to take a few years, based on data from previous Bearhawk builders.

Bearhawk Delivers First Two-Seat Companions

Last edited:

MiG-29SMT

Senior Member

- Joined

- Jan 12, 2020

- Messages

- 3,915

- Likes

- 4,825

Bearhawk Aircraft has been sold by its founder Mark Goldberg to Virgil Irwin, one of its clients and builders. The missionary pilot plans to base an expanded builder-assist program in Fairview, Oklahoma.

Bearhawk offers five different rugged STOL models specifically designed for the back country. The LSA and Patrol offer tandem, two-seat configurations, the Companion offers 2 + 2 seating, while the Four is, well, a four-place model. The Bearcat Five actually offers seating for six and has a gross weight rating of 3,000 lb. with a useful load of 1,400 lb. All are designed as taildraggers with options for floats or skis.

“We want to reassure customers that all current orders will be honoured, and we will continue to provide you the same great airplanes,” said Irwin. “We look forward to serving the Bearhawk community and earning your trust and support.”

Mark Goldberg established his kit manufacturing facility in Atlixco, a town of 140,000 about 85 km southeast of Mexico City, after taking a liking to the place and its people while travelling the region in his younger days. Goldberg reportedly was adamant that the manufacturing facility in Mexico remain in place.

The original Bearhawk, now named the Bearhawk Four, was designed by Bob Barrows in the late 1990s. There are currently 22 Bearhawks on the Transport Canada registry.

canadianaviator.com

canadianaviator.com

Bearhawk offers five different rugged STOL models specifically designed for the back country. The LSA and Patrol offer tandem, two-seat configurations, the Companion offers 2 + 2 seating, while the Four is, well, a four-place model. The Bearcat Five actually offers seating for six and has a gross weight rating of 3,000 lb. with a useful load of 1,400 lb. All are designed as taildraggers with options for floats or skis.

“We want to reassure customers that all current orders will be honoured, and we will continue to provide you the same great airplanes,” said Irwin. “We look forward to serving the Bearhawk community and earning your trust and support.”

Mark Goldberg established his kit manufacturing facility in Atlixco, a town of 140,000 about 85 km southeast of Mexico City, after taking a liking to the place and its people while travelling the region in his younger days. Goldberg reportedly was adamant that the manufacturing facility in Mexico remain in place.

The original Bearhawk, now named the Bearhawk Four, was designed by Bob Barrows in the late 1990s. There are currently 22 Bearhawks on the Transport Canada registry.

Bearhawk Aircraft Changes Hands - Canadian Aviator Magazine

Bearhawk Aircraft has been sold by its founder Mark Goldberg to Virgil Irwin, one of its clients and builders. The missionary pilot plans to base an expanded builder-assist program in Fairview, Oklahoma. Bearhawk offers five [...]

| Thread starter | Similar threads | Forum | Replies | Date |

|---|---|---|---|---|

|

|

China's exploitation of Latin American natural resources raises concer | Americas | 0 | |

|

|

Latin and South American Music | Members Corner | 7 | |

|

|

Venezuela's Chavez : Did U.S. give Latin American leaders cancer ? | Americas | 0 | |

|

|

US is Covertly Infecting Latin American Leaders with Cancer? | Americas | 29 |

Latest Replies

-

Indian Special Forces

- lexz09

-

Infrastructure and Energy Sector

- mamamia12

-

AgniKul Cosmos - Updates & Activities

- FalconSlayers

-

Jokes Thread

- Hindu Nationalist

-

Idiotic Musings From Firangistan

- Love Charger

-

Idiotic Sinking state of Bangladesh

- thebakofbakchod

Global Defence

-

Small arms and Light Weapons

- NoobWannaLearn

-

Aircraft Crash Notification

- mist_consecutive

-

Turkish defense industry news updates

- Satish Sharma

-

F-35 Joint Strike Fighter

- SwordOfDarkness

-

World Police Force/Special Units/SWATS

- Vishalreddy3

-

Battle of Stonne 1940

- Picard

-

Rafale in Croatian Air Force

- Picard

New threads

-

Chinese Space Archives

- skywatcher

- Replies: 2

-

Rushi Sunak Announces UK General Elections on Jul 4

- ezsasa

- Replies: 10

-

NYT: Xi’s Warm Embrace of Putin in China Is a Defiance of the West

- skywatcher

- Replies: 1

-

Iran President Helicopter Crash

- Cheepek

- Replies: 198

Articles

-

India Strikes Back: Operation Snow Leopard - Part 1

- mist_consecutive

- Replies: 9

-

Aftermath Galwan : Who holds the fort ?

- mist_consecutive

- Replies: 33

-

The Terrible Cost of Presidential Racism(Nixon & Kissinger towards India).

- ezsasa

- Replies: 40

-

Modern BVR Air Combat - Part 2

- mist_consecutive

- Replies: 22

-

Civil & Military Bureaucracy and related discussions

- daya

- Replies: 32